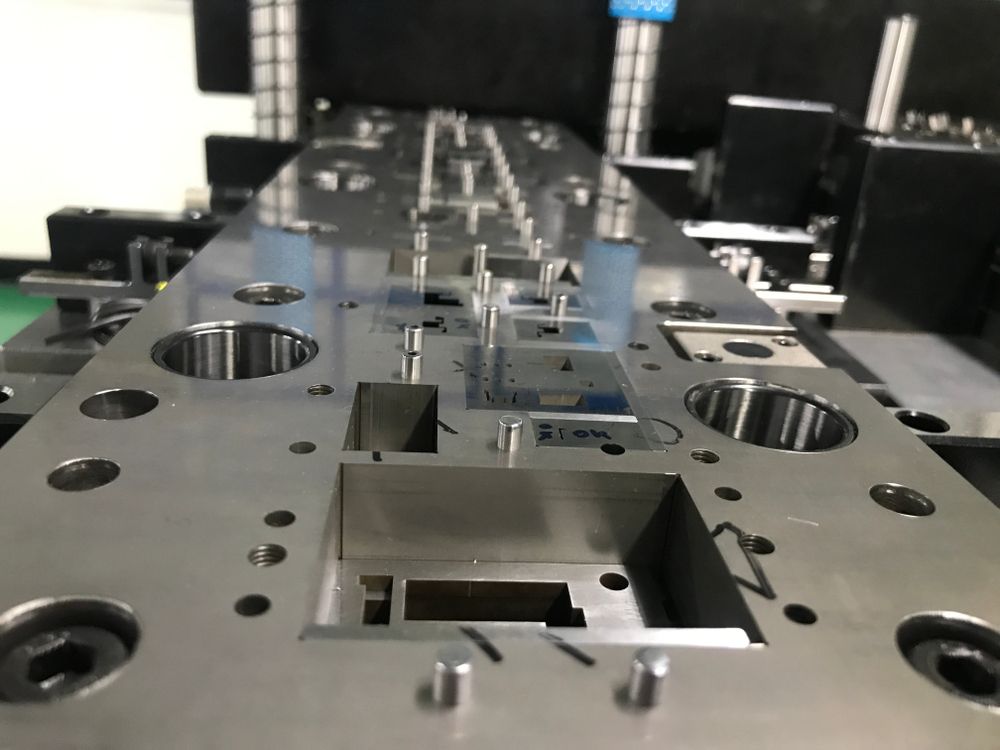

A metal stamping die is a tool used to cut and shape a metal sheet once a press applies pressure. But when you take a closer look into what a die consists of and how it operates, it’s easy to get a bit tangled up in the weeds. We’re here to help you sort it all out.

Here’s a foolproof guide to some of the most essential die components and their functions.

8 Basic Die Components and Their Functions

This is by no means an exhaustive list of every part that could be placed in a die. It’s just a starting point to learn more about dies and how they function. If you have questions about a die component not mentioned in this article, please don’t hesitate to reach out to our team.

1. Die Plates (Shoes, Sets)

Also known as die shoes and die sets, die plates serve as the foundation for where other die tools and components are mounted. They hold many of the other components on this list (punches, buttons, springs, etc.) in place.

Die plates are typically made from steel, but aluminum is a feasible option as well. It’s lightweight and can be combined with alloys for added strength.

2. Die Guide Pins and Bushings

Die guide pins work in conjunction with guide bushings to align the upper and lower die plates with accuracy. They are manufactured to tolerances within .0001” (also known as a “tenth”) to ensure precise positioning.

There are two main types of die guide pins: friction pins and ball-bearing pins.

- Straight guide pins are a tad smaller than their complementary bushing’s inner diameter.

- Ball-bearing guide pins glide on a sequence of ball bearings within an aluminum ball cage. This allows the bearings to rotate but prevents them from falling out.

There isn’t necessarily a “best” choice between these two types of guide pins. It just depends on what fits best within your die and what your goal is for your end product. Ball bearing pins are easier to separate die halves and have become industry standard because of their ease of use. Standard die pins still have their use in providing accurate guidance but are more difficult to separate from their guide bushing.

3. Die Punches

Die punches are the tools that actually press into the metal sheet and transform it. They’re fixed within the die retainer (more on that later). They can either bend or punch a hole through the metal, depending on their nose shape. Nose shapes can be round, oblong, square, rectangle, hex, flatted-round, or customized.

Aside from nose shape, die punches are also available in a number of shank diameters and lengths. You can check out our Inch and Metric catalogs for full details.

4. Die Buttons

Die buttons are die punches’ counterparts. They provide the opposite cutting edge in which die punches are inserted. To mirror the die punches, die buttons are also available in a number of styles, shapes, and tolerances. However, they generally offset larger than the punch nose by 5-10% of the pierced material thickness. This is referred to as the “die break,” which allows space between the punch and the button so that cutting can take place and a hole can be created.

5. Die Springs

Die springs are helical, high-force compression springs. They provide the amount of force needed to hold metal sheets in place while they’re being transformed by the die.

There are many types of die springs, but the two most common are mechanical and nitrogen gas die springs.

- Mechanical die springs are the standard type of die spring, also known as wire coil springs.

- Nitrogen gas die springs use compressed nitrogen gas contained within a cylinder to exert force within the die.

Check out this article to determine whether mechanical or nitrogen gas die springs are right for your application.

6. Die Retainers

Die retainers are placed on die plates to hold cutting and forming die components (e.g. punches, buttons) in place. They come in various types that serve different purposes. Some popular ones include:

At Moeller Precision Tool, our True-Set™ line of retainers are the best in the industry. Manufactured from a single through-hardened piece of high-quality alloy steel, the design enables great punch positioning and prevents stacking tolerance errors.

Moeller also manufactures special per-print multi-hole retainers in True-Set™ style that reduce die assembly time and eliminate the need for backing plates and plugs.

7. Custom Die Details

All of the die components above can be customized for your application. They can be machined to meet per-spec shapes, sizes, etc.

There are also a number of add-ons you can incorporate within your die. Check out our True Strip™ mechanical stripppers, urethane strippers, shim plates, and backing plates for examples.

Get Standard and Special Die Components at Moeller Precision Tool

At Moeller Precision Tool, we’re your trusted global partner for standard and special die components. We use years of industry research, state-of-the-art equipment, and best quality assurance practices to manufacture the tools die builders like you need to achieve a job well done.

We specialize in the following die components:

- Die punches

- Die buttons

- Die springs

- Die retainers

- Custom die details and accessories

We have many reputable partners that can help you with die plates, guide pins, and bushings as well.

If you’d like more information on how Moeller Precision Tool can help you get the high-quality die components you need, contact us online today.